At Bilboaero, we’re here to simplify the complexities of panel building for experimental aircraft, allowing you to choose as much or as little of our help as needed

Building the perfect panel for our experimental airplanes is a complex task that can feel overwhelming. Choosing the right equipment, determining optimal placement, and ensuring seamless connectivity require expertise that may not be familiar to everyone.

At Bilboaero, we understand these challenges and are here to guide you through the intricacies of panel building and avionics installation. Drawing from our experience as builders in the experimental aviation community, we’ve navigated these processes for our own aircraft and for numerous friends.

While many businesses offer comprehensive custom panel and avionics solutions, we noticed that these often come as packaged deals, making them financially out of reach for some enthusiasts. This realization prompted us to start building panels ourselves.

We’ve taken a different approach by “un-bundling” the custom panel construction process. This means you can tailor our services to fit your exact needs, whether you require assistance with design, CNC routing, wiring harness assembly, or any combination thereof. Our goal is to empower you to choose the level of support that best suits your project.

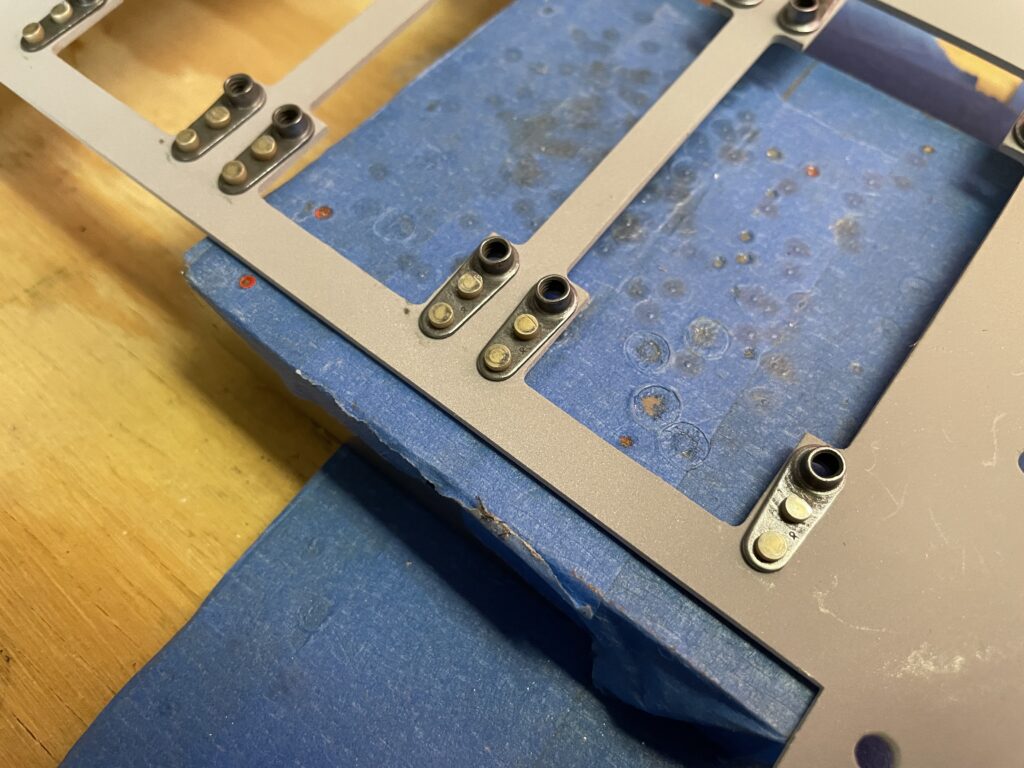

One major difference in how we approach panel design and construction is our belief in making things easy to take apart and maintain. As a result, our primary focus is on modularity. We design with the aim of simplifying maintenance and upgrades. Check out our blog and shop to see some of the products we designed for our panels. Many of them are not new ideas, but what sets us apart is that we integrate these ideas and concepts into our designs.

Below, we outline our step-by-step approach to custom panel design at Bilboaero, providing you with the flexibility to decide how we can best assist you in achieving your vision.

Panel Design

“A picture is worth a thousand words”

From vision to a virtual representation of your panel. Understand how it will look and how everything fits together. [Click here for more details].

Avionics Diagram Creation

“Where do all these wires go?”

We work hard to create the best possible wiring diagrams. The end goal is to make it easy for you to understand what to connect where. [Click here for more details].

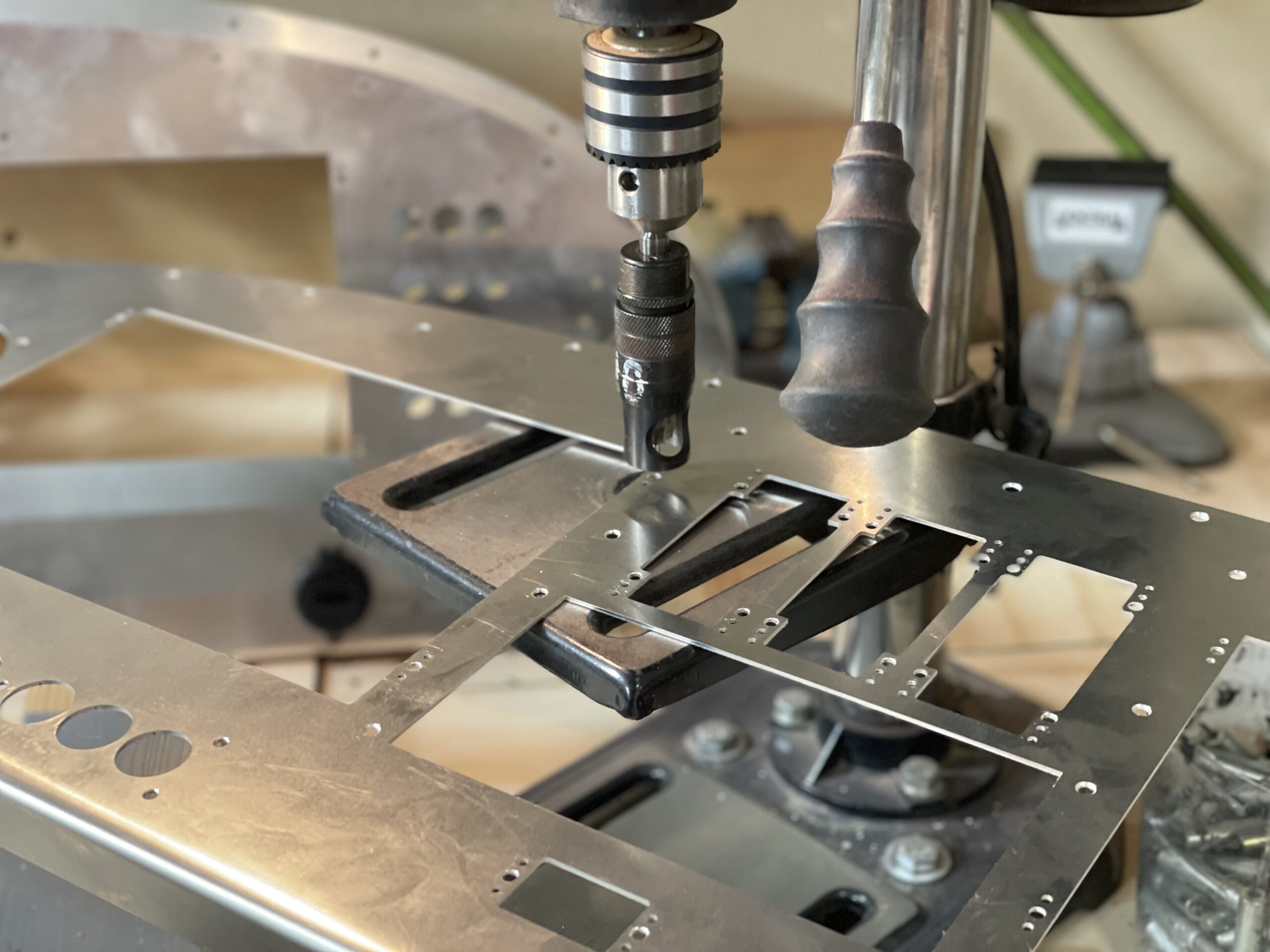

CNC Routing

“Let’s make aluminum (or composite) chips”

We can transform your design from blueprint into reality. We have access to various methods of cutting metal and composites. From laser cutting to CNC milling, the results are incredibly accurate with very small tolerances. [Click here for more details].

Paint & Labeling

“Our colors or yours, you decide”

We offer the option to paint and label your panel through either laser engraving or vinyl stickers. Custom colors available. [Click here for more details].

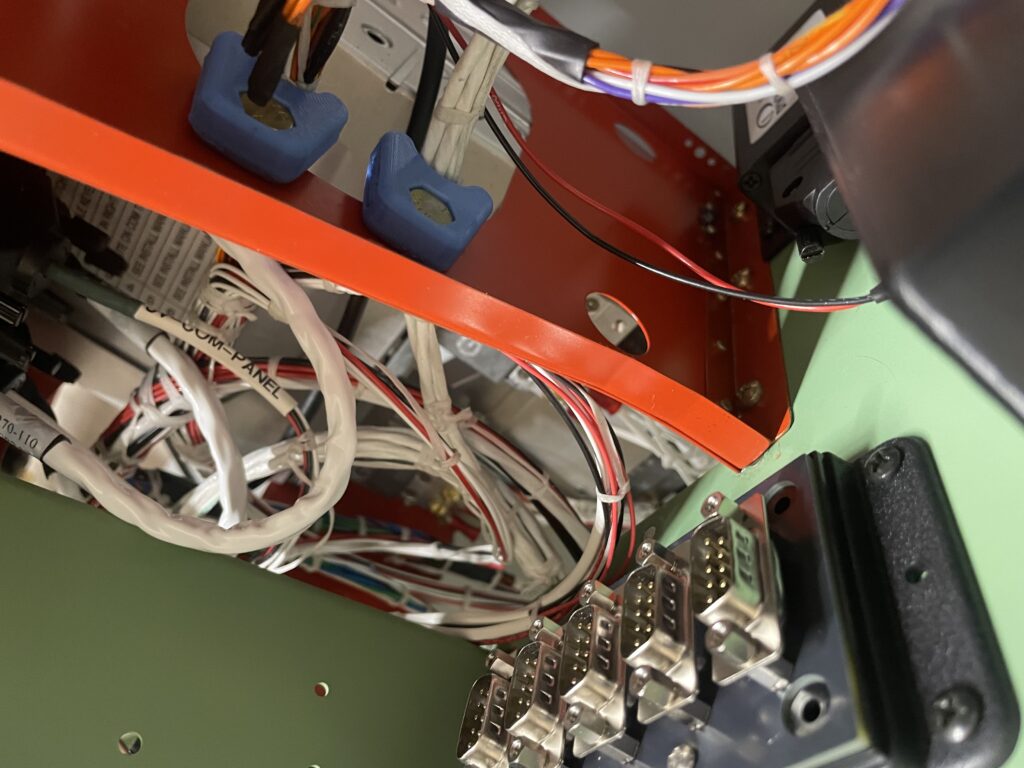

Harness Fabrication

“Wires into harnesses, and everything in between”

With the creation of our wiring diagrams comes the option of us fabricating the different wiring harnesses needed. [Click here for more details].

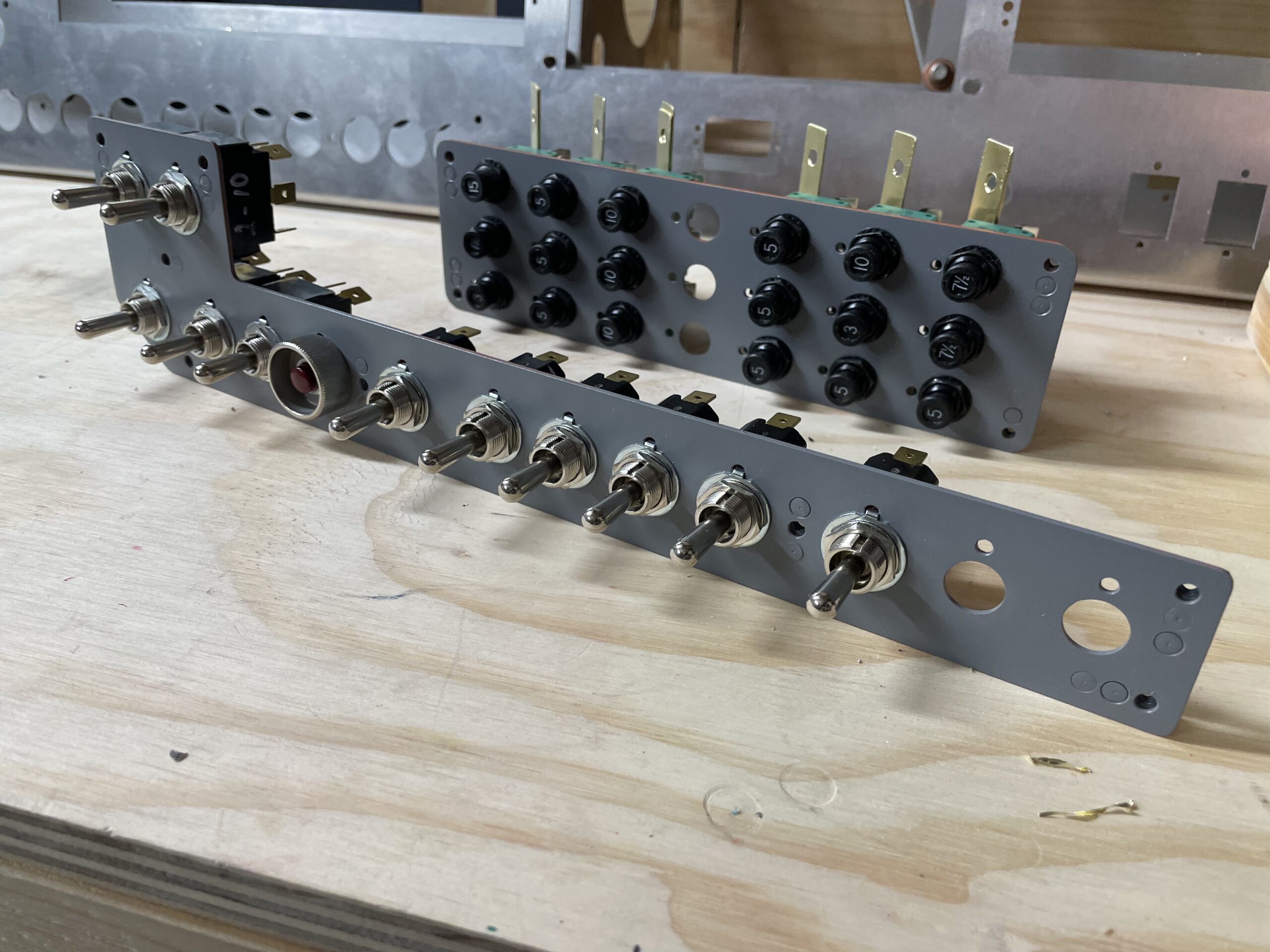

Panel Assembly

“All comes together”

As a final step, if you decide to task us with the full production of your custom panel, we will assemble and test as much as possible. Certain things will depend on your specific airplane, but we will provide you with the information and documentation you need to install everything in place.

Details like power and ground connections and long wiring from switches to different components throughout the airplane will need to be addressed by you during installation.